See This Report on Inventory Management

Wiki Article

All About Inventory Management

Table of ContentsAn Unbiased View of Inventory ManagementThe Ultimate Guide To Inventory ManagementGetting My Inventory Management To WorkFascination About Inventory ManagementMore About Inventory Management

The periodic supply system is a technique of inventory assessment for monetary reporting functions in which a physical matter of the inventory is performed at certain intervals. This accountancy approach takes inventory at the start of a duration, includes new supply acquisitions during the duration as well as subtracts finishing stock to acquire the expense of goods offered (COGS).They can connect several data points to the number, consisting of the provider, item measurements, weight, as well as even variable data, such as the number of are in supply. RFID or superhigh frequency recognition is a system that wirelessly sends the identification of a product in the form of an unique serial number to track things and offer detailed item info.

Some Known Facts About Inventory Management.

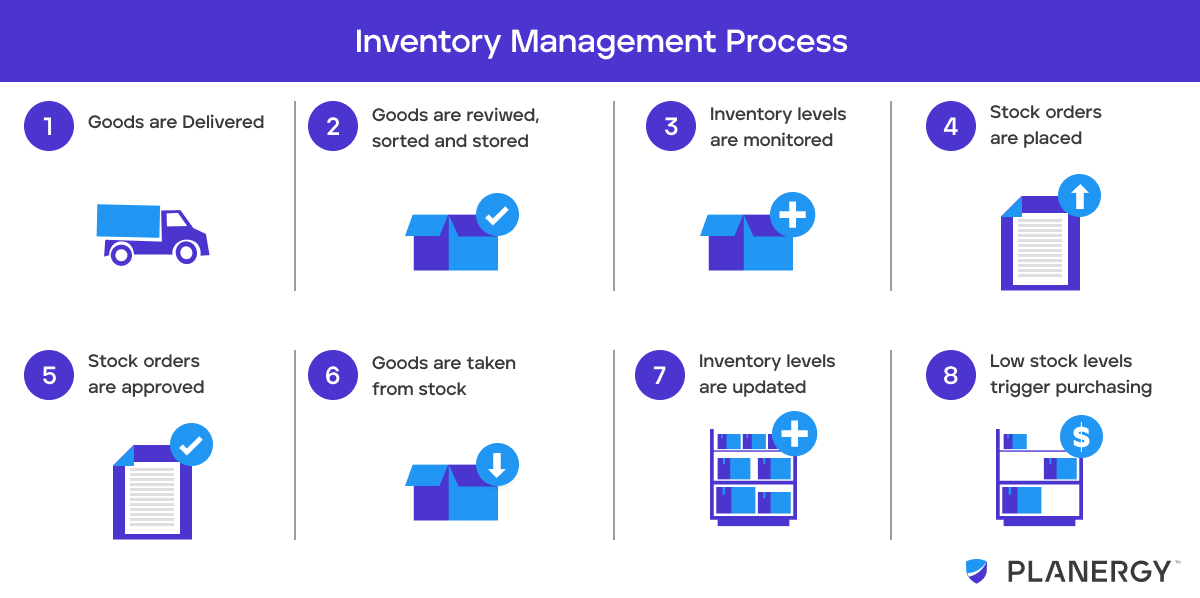

Stock administration refers to the procedure of keeping, getting, and also marketing of items and also solutions. The self-control also includes the monitoring of numerous products as well as processes. One of one of the most important aspects of inventory administration is handling the circulation of basic materials from their procurement to finished items. The goal is to minimize overstocks and also boost effectiveness to make sure that jobs can remain on time as well as within budget.For circumstances, an oil depot can store a substantial inventory for a long period of time. Or for services that sell perishable products, such as fast-fashion products, going on top of your supply can be really pricey. One means to account for inventory is by organizing it right into four categories: first-in-first-out, last-in-first-out, weighted-average, and also first-in-first-out.

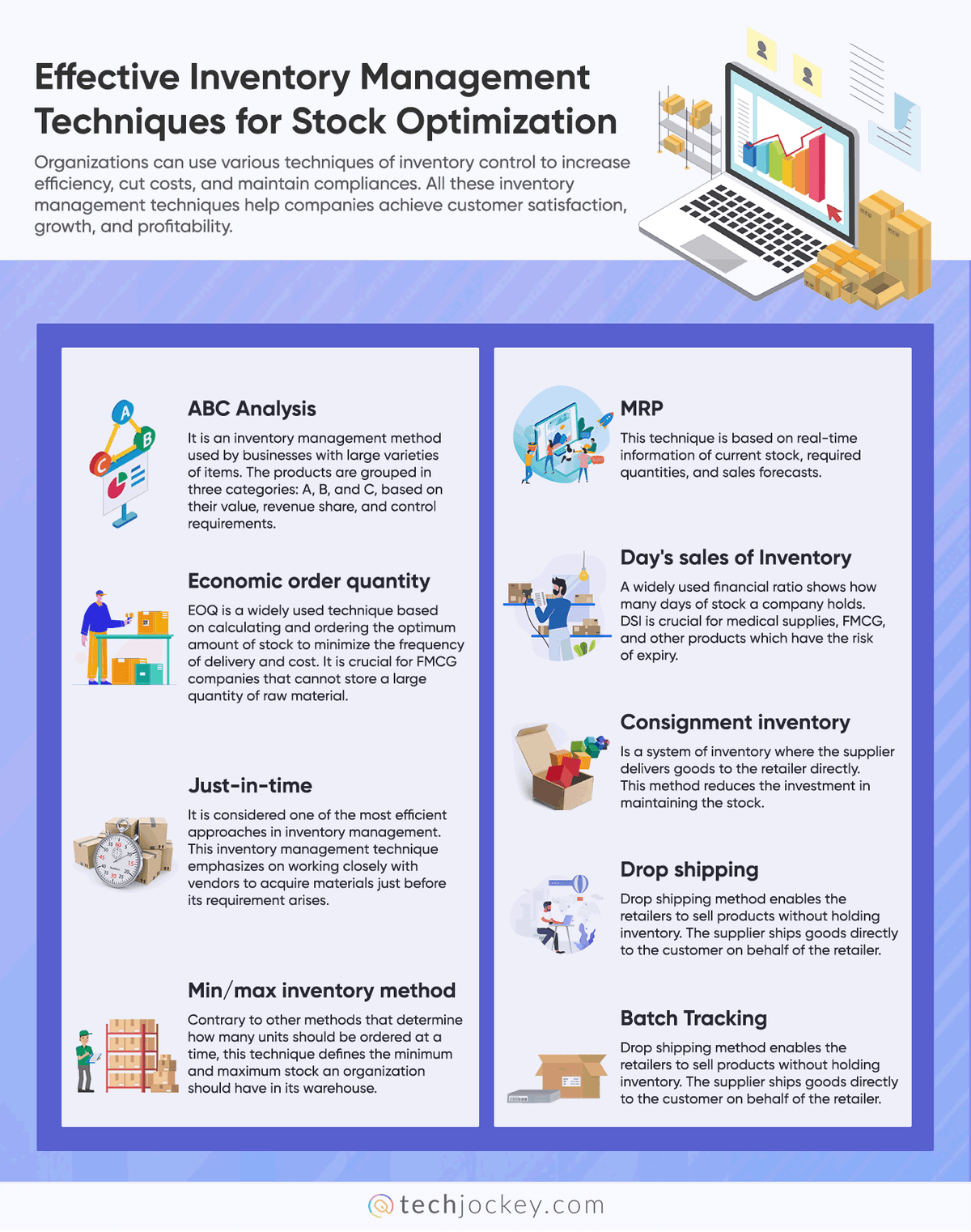

Depending upon the kind of firm that it is managing, various inventory administration techniques are used. Some of these include JIT, material need planning, as well as days sales of inventory. Other methods of analyzing supply can likewise be used relying on national and neighborhood laws. For instance, the SEC needs public business to report the existence of a so-called LIFO book.

7 Easy Facts About Inventory Management Shown

Find out a lot more regarding supply administration from Walton College's Supply Chain Management program's introduction on the subject covering everything from projecting to point versions: Among the most beneficial properties of a business is its stock. Inventory Management. In various industries, such as retail, food services, and also manufacturing, a lack of stock can have detrimental effects.Having a huge stock can also lead to a decrease in sales. Both for small companies and large corporations, having a proper stock management system is really important for any type of service.

This is particularly vital for brand names looking to come to be a much more customer-centric organization. Balancing the risks of overstocks as well as shortages is an especially difficult procedure for business with intricate supply chains. A firm's inventory is normally an existing asset that it prepares to market within a year. Inventory Management. It needs to be gauged as well as counted consistently to be thought about an existing asset.

The Ultimate Guide To Inventory Management

Not only will it offer to improve efficiency, however it's additionally helpful for stopping theft with the aid of item tracking and also protection. Managers can additionally aim to utilize their inventory management plan to monitor sales procedures which leads imp source to much better service.

Offering consumers a number of various types of internationally-grown produce in both natural as well as non-organic ranges at an affordable price, even when the fruits as well as vegetables aren't in period, is a modern marvel many thanks partly to stock management. Supervising stock in real time as well as also establishing up automated replenishment systems is mission-critical to lots of.

The 10-Second Trick For Inventory Management

6 million plans from their brand name to third-party sellers per day. Their Smart Storage facility utilizes robotic as well as human aid to finish the job, but it's supply administration that keeps everything rolling. According to Technology Vision, "Amazon.com's administration strategy, along with all that automation, have actually made the company tremendously lean and indicate by historical requirements." The inventory administration of bathroom tissue firms remained in the warm seat in early 2020 as panic-buying resulted in lacks nationwide.

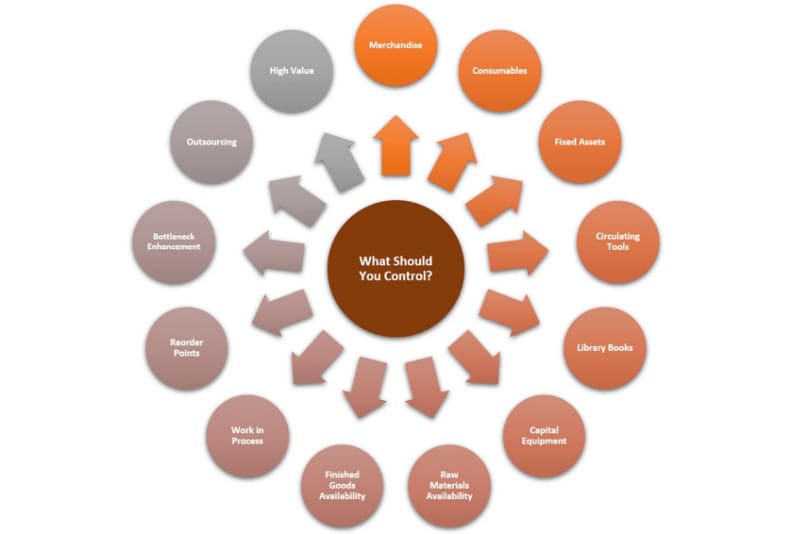

Below are the major kinds you should understand: Resources, This describes pieces of your product that need to be delivered to you as well as constructed by your team. Stock systems that track these need to account for supplier timelines. In development, Products made from resources as well as are currently being put together or grouped loss under this group.

Report this wiki page